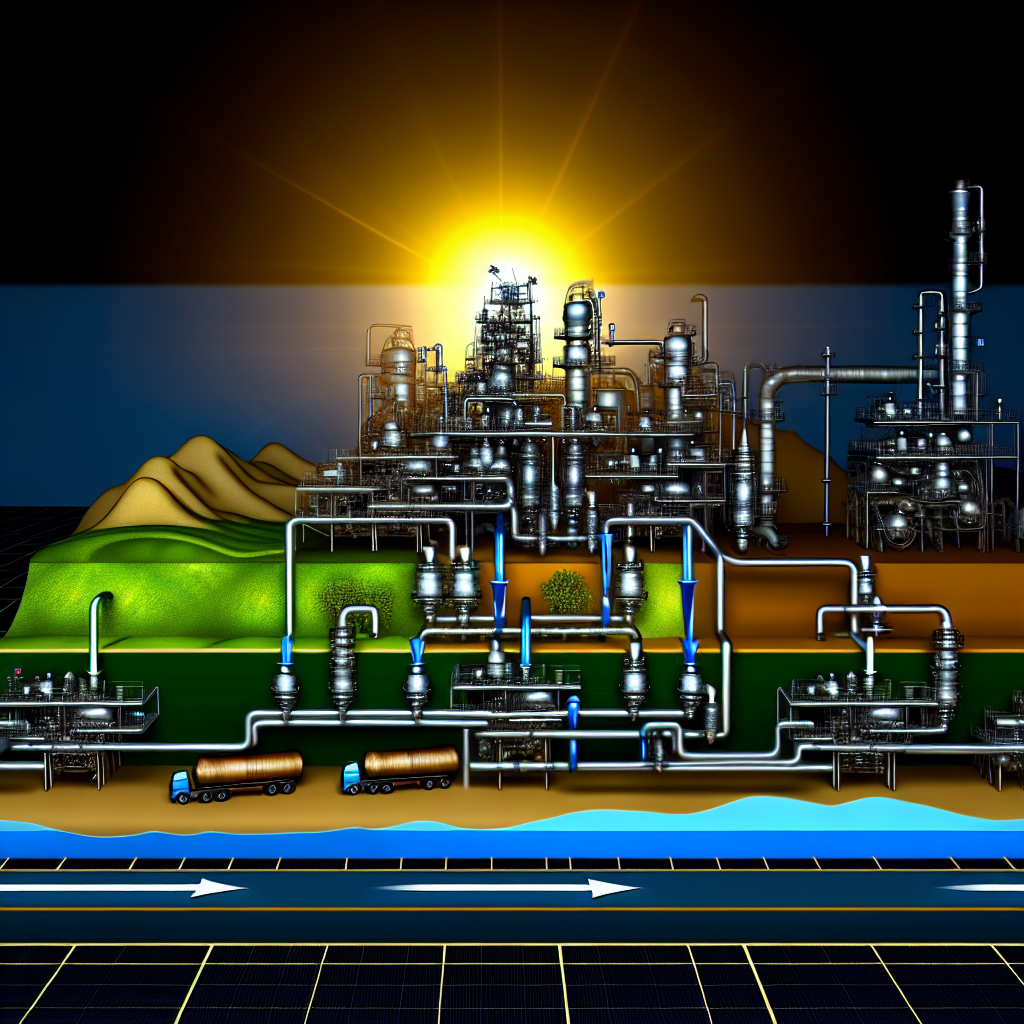

Petroleum refining is a complex process vital to producing the fuels and products we rely on daily. By transforming crude oil into usable forms like gasoline, diesel, and jet fuel, refineries play a crucial role in global energy supplies. In this article, we will explore the fundamental processes involved in refining petroleum, broken down into understandable steps.

Distillation: Separating Crude Oil Into Components

The first crucial step in petroleum refining is **distillation**, often called **fractionation**. Crude oil is a mixture of various hydrocarbons with different boiling points. The refining process begins by heating the crude oil in a large, vertical distillation column called a **fractionating tower**. As the oil heats up to temperatures of around 350–400°C, its components vaporize at different temperatures.

These vapors then ascend the tower, where cooler temperatures cause them to condense into liquids at different levels based on their boiling points. This separation results in **fractions** such as gases, naphtha, kerosene, diesel, and heavier residues. Each fraction is then drawn off for further processing or use.

While distillation effectively separates crude oil based on physical properties, it does not convert the hydrocarbons into useful fuels. Therefore, further methods are necessary to modify and upgrade these fractions.

Conversion and Treatment: Enhancing Fuel Quality

Following distillation, the refining process involves **conversion processes** like **catalytic cracking**, **hydrocracking**, and **coking**. These processes break down larger, heavier hydrocarbon molecules into lighter, more valuable fuels such as gasoline and jet fuel.

**Catalytic cracking** uses catalysts to accelerate breaking long-chain hydrocarbons into shorter ones, increasing gasoline yield. **Hydrocracking** incorporates hydrogen to improve product quality, reducing sulfur content and producing cleaner fuels. **Coking** involves heating residual heavy fractions to produce lighter products and petroleum coke, a carbon-rich solid used in industrial applications.

Additionally, **treatment and refining processes** refine these fractions further, removing impurities like sulfur, nitrogen, and metals. Techniques such as **hydrotreating** and **desulfurization** ensure fuels meet environmental standards and quality specifications.

This stage is essential for transforming raw distillation outputs into market-ready fuels and products that meet strict regulatory requirements, ensuring safety and environmental compliance.

Conclusion

Petroleum refining combines **distillation** to separate crude oil into distinct fractions, followed by advanced **conversion and treatment** processes to enhance fuel quality and meet consumer demands. These interconnected steps enable the production of essential fuels and products from raw crude oil efficiently and responsibly. Understanding these processes highlights the critical role refineries play in our daily energy consumption and industrial needs.