Understanding the process of coil winding for a 0.5 HP motor is essential for ensuring optimal motor performance and longevity. In this article, we will explore the key aspects of complete coil winding, including techniques, tools, and best practices, to help electrical professionals and enthusiasts achieve high-quality results.

Understanding the Coil Winding Process for 0.5 HP Motors

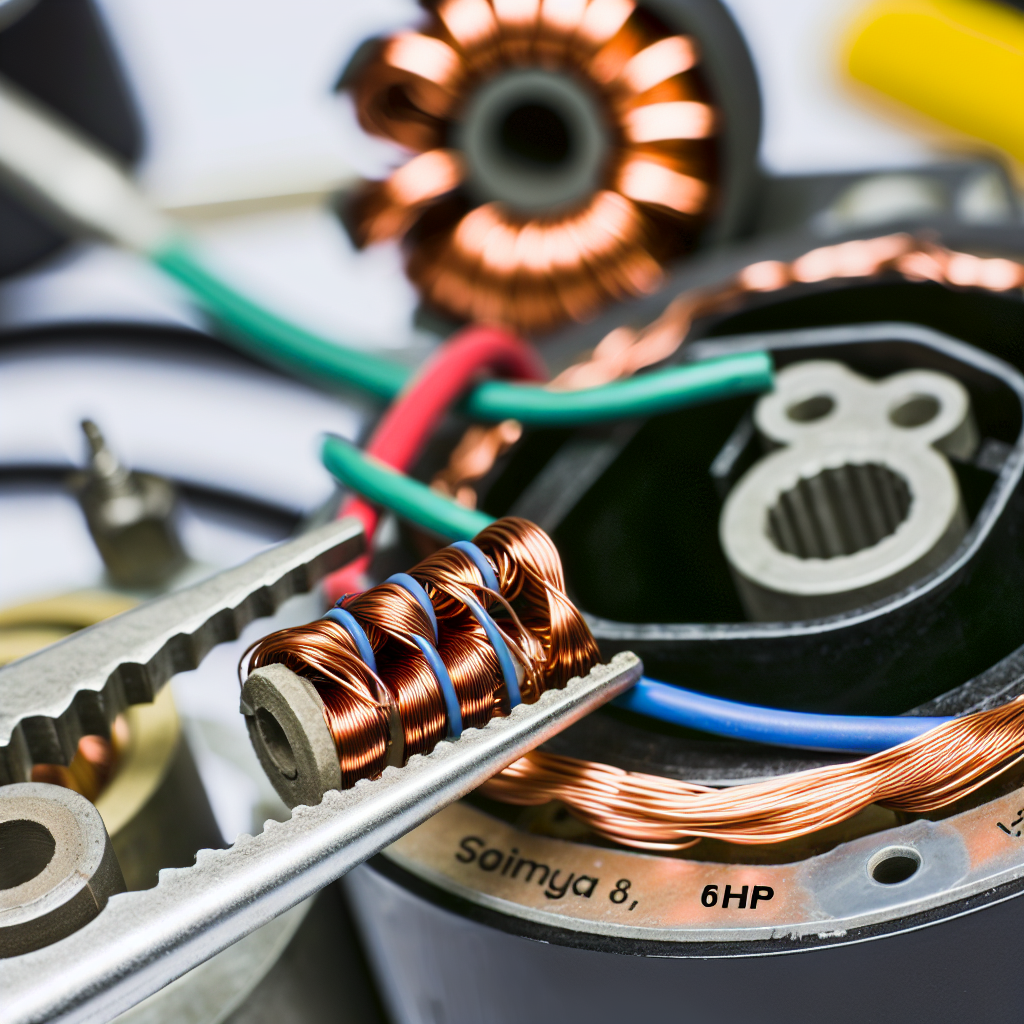

The coil winding process for a 0.5 HP motor involves several critical steps that determine the motor’s efficiency, durability, and overall performance. The process begins with selecting the appropriate wire gauge and insulation material, which must withstand operational temperatures and electrical loads. The winding itself must be precise, ensuring that each turn is tightly wound and evenly spaced to prevent hot spots or uneven wear.

Specialized tools such as coil winding machines, mandrels, and tensioners are used to maintain consistency throughout the winding process. Proper insulation between the coils is essential to prevent short circuits, and curing or varnishing may be applied post-winding to enhance durability. Attention to detail during each phase ensures the motor operates smoothly and reliably.

Best Practices and Tips for Complete Coil Winding

Successful coil winding for a 0.5 HP motor hinges on adherence to best practices, including:

- Careful wire preparation: Ensure wires are clean, well-insulated, and cut to precise lengths.

- Consistent tension application: Maintain uniform tension during winding to prevent uneven coils and mechanical stress.

- Accurate winding pattern: Follow the correct winding sequence to match the motor’s design specifications.

- Proper insulation and curing: Use high-quality insulating materials and allow adequate curing time for longevity.

- Testing after winding: Conduct electrical tests such as insulation resistance and continuity checks to verify quality before assembly.

Incorporating these practices ensures that the finished coil withstands operational stresses, reduces maintenance needs, and enhances the overall efficiency of the motor.

Conclusion

Mastering the coil winding process for a 0.5 HP motor is vital for delivering reliable electrical performance. By understanding the proper techniques and adhering to best practices, technicians can produce high-quality coils that boost motor efficiency and lifespan. Continuous learning and attention to detail are key to achieving excellence in electrical coil winding.